Seawater Reverse Osmosis (SWRO) Plant is designed with a capacity of 60,000 cubic meter per day (m³/day) to provide the university with potable water that meets WHO quality standards. The produced water is then stored in the potable water tanks and distributed to KAUST Campus and Community Networks. The distribution network has a length of around 85 km, that supply potable water, irrigation water and fire water to all end-users in KAUST.

To meet the future demands, KAUST has undertaken “KAUST Research Park Utilities Expansion Project”. The project includes utilization of the provisions available at the existing SWRO plant to increase its capacity to 50,000 cubic meter per day.

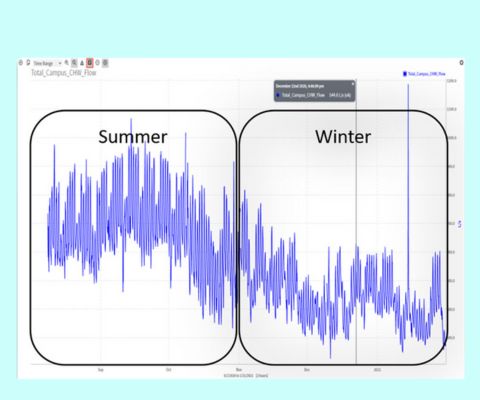

One zone, one network and delta P reduction: This was done to compensate the effects of low return water temperature from end users particularly from R & F side in winter season. As a trial in Feb 2022, it resulted in savings of approximately 90,000 SAR / month.

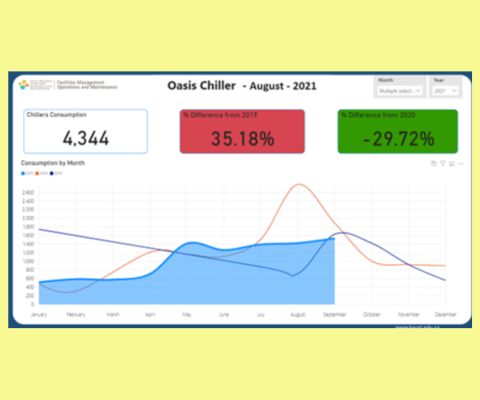

Running of extra cooling towers: Extra cooling tower is operated which leads to better heat transfer at the condenser and consequently at the evaporator of the running trains. It then leads to delay the starting of another chiller train by approximately 4 hours. This is being done for approximately 90 days in a year depending on ambient climate, end user loads etc. This leads to a saving of approximately 98,000 SAR per year.

To enhance thermal comfort and prevent overcooling, KAUST implemented measures to reduce AC air supply in certain areas:

This approach effectively balances comfort and energy efficiency, contributing to KAUST's sustainability goals.

Significant energy saved.

.jpg?sfvrsn=3ba23c7f_0)

To be able to achieve thermal comfort and avoid over cooling, reduction of AC air supply in some locations was considered:

An action to shutoff the AC Units in Boathouse and Golf Maintenance House was made as these spaces do not require cooling, only ventilation is needed. Additional ventilation might be required (under evaluation).

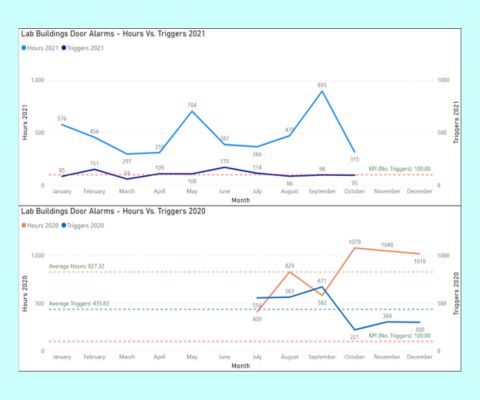

HSE and FM joined forces to review the ventilation levels of all laboratories in KAUST. Ventilation and cooling equate for more than 70% of the energy bill and carbon footprint of lab buildings in KAUST. By analysis of the Air Changes per Hour (ACH) and adjusting this value in line with international standards, FM and HSE were able to provide energy savings without compromising the safety of users, achieving a reducing of 16%.